0

3452

A Guide to Preparing ID Solutions for UK Enrolment

ID cards play a vital role in educational environments by ensuring that students and staff are easily identifiable, helping to restrict access to authorised individuals only. One of the most useful features of ID card management systems is their versatility and adaptability — our in-house exp..

0

3176

Built to enhance your ID card production, the Evolis Agilia is a top-tier retransfer printer, designed for producing high quality, cost-efficient, and durable images onto your cards at an impressive 600dpi resolution. The retransfer technology effortlessly prints onto your cards using an ink ribbon and film.

Here are some of the main features Agi..

0

3102

A local authority council was looking for an easy, cost-effective solution for printing bus passes for their residents. With a high level of production required, the council needed a high-quality printing solution that still allowed them to overprint details on demand.

They contacted Plastic-ID looking for an affordable, simple solution.

The Ch..

0

2087

Retransfer technology has gained popularity among organisations that are seeking high-quality and durable ID cards. Retransfer printers can be set apart from other models thanks to the printing process they use, which involves transferring the printed image onto a film before applying it to the card’s surface. This results in superior print quali..

0

3098

As all companies know, health and safety is paramount across the board. All members of employees have the right to know that their personal health and safety are taken care of when they are at work, and businesses have a responsibility to provide quality health and safety measures to all of their employees.

Whilst a lot of staff work alongside a..

0

3165

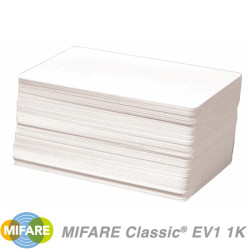

Smart cards and readers are commonplace across a range of businesses. They offer a range of security benefits by allowing you to grant and limit access to certain areas, so if you handle sensitive information, only certified people can enter areas where it is stored.

These systems, often called access control systems, allow you to hand out smar..

0

3463

Table of Contents

1. Why Should Organisations Use Plastic ID Cards?

2. ID Card Design and Security Features

Chapter 1: Why Should Organisations Use Plastic ID Cards?

Plastic ID cards are one of the unsung heroes in an office environment. Small but mighty, PVC ID cards provide a look of professionalism, improve office morale, and also of..

0

3351

A world-famous education institute with a long and rich tradition of education featured a 600-year-old library, which has provided information and support to generations of students over the centuries. With an ever-expanding catalogue of over 8 million books, the university’s library is a vital resource for students.

To ensure the library contin..

0

3094

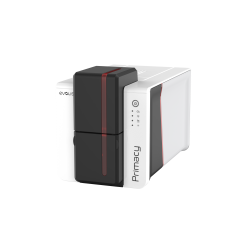

If your business is looking to start printing and creating your own ID cards, it is important that you get the right kind of printer to suit your business needs.

Every business is different and has individual requirements from your ID cards. By understanding what each style of printer offers, you can make an informed decision on which type of ID ..

0

3729

When implementing an ID card system in your business, it’s important to note that data protection regulations must still be adhered to.

Different parts of your card printing set-up can be compromised. As photo ID cards and name badges contain personal data, you must take steps to ensure the information you are printing is secure.

ID card print..

0

3195

ID cards typically come in a standard size. The most common ID cards are 86mm x 54mm, also known as CR80. This is the size of driving licences, credit cards and business cards, however, there are further options when it comes to ID card printing. Other sizes include large format cards – with XL cards measuring at 100m x 70mm and 2XL measuring even ..

0

3197

When it comes to your events, you need professional, high-quality event badges to ensure your event staff look professional and put together. Alongside boosting the image of your event, having visible name badges is important for event security for your visitors and staff. Here at Plastic-ID, we’ve got all the essentials you need to ensure you have..

-770x257w.jpg)

-300x225h.png)

-300x225h.png)